Sanivap,

le bionettoyage vapeur

Accueil > Sanivap

Leader dans la vapeur !

Avec plus de 15 ans d’expérience, Sanivap est aujourd’hui le leader et la référence incontestée dans le domaine du bionettoyage vapeur.

Sanivap offre une gamme de produits très efficaces et fiables ainsi que des services de formation utilisateurs et des services techniques adaptés aux besoins des professionnels de l’hygiène.

La méthode vapeur Sanivap

Les dispositifs Sanivap produisent une vapeur à haute température efficace en terme de détergence : élimination des souillures et des biofilms, aucune trace résiduelles de produit chimique.

La vapeur à haute température (150° C) et sous pression (5 bars) fournit une puissance de nettoyage à toute épreuve. La vapeur obtenue, dite neutre, c’est-à-dire exempte de tous minéraux et déchargée de toute conductivité électrique, neutralise les charges statiques des formations poussiéreuses. La vapeur agit alors, comme une substance gazeuse. Sa chaleur fait fondre les graisses en libérant et en supprimant toutes les particules de saleté qui la composent. Elle pénètre dans les moindres recoins pour éliminer les salissures rendant le nettoyage plus simple, efficace et durable. Enfin, la vapeur élimine les dépôts et biofilms sur les surfaces.

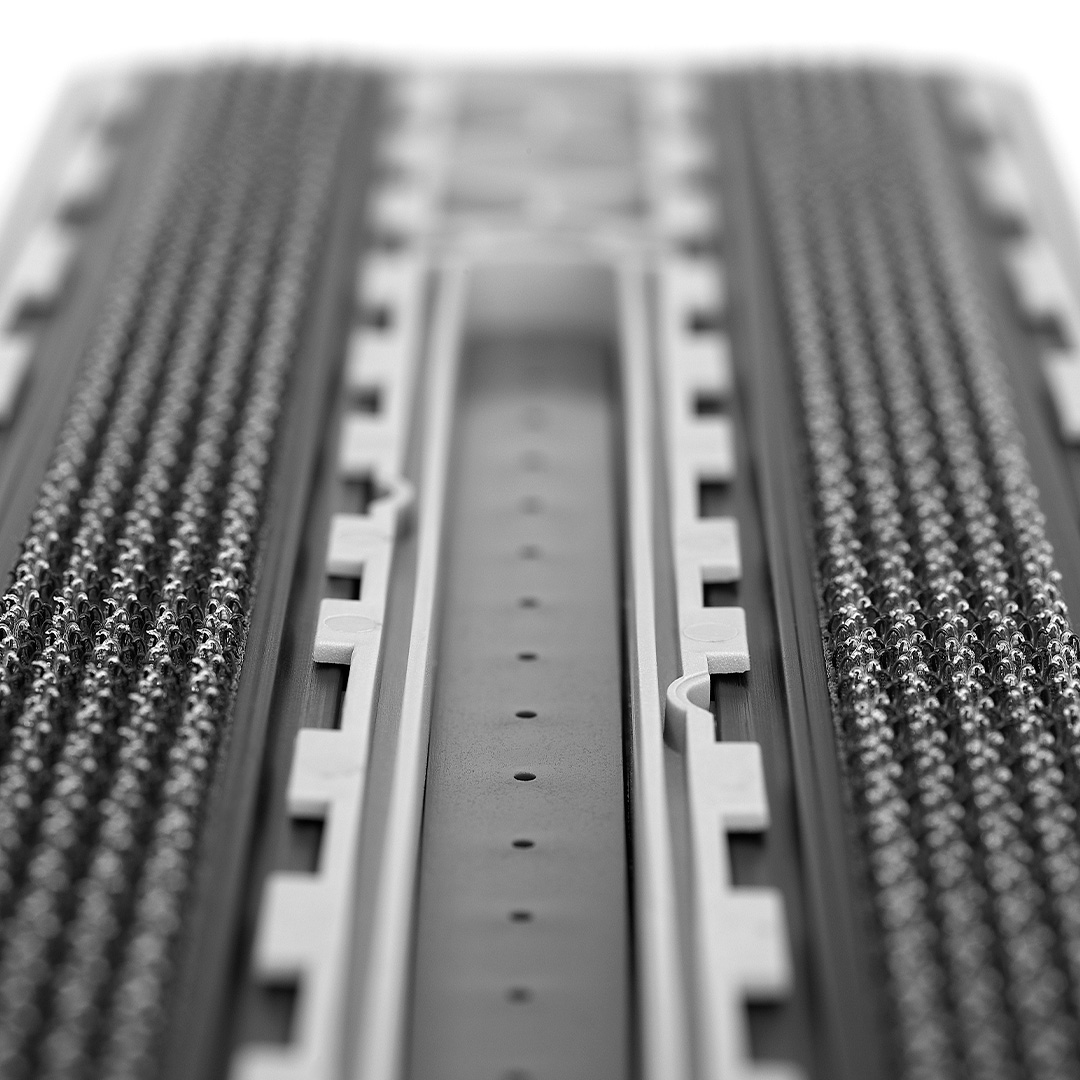

L’utilisation de microfibres avec les accessoires assure une parfaite élimination de toutes les salissures.

Une efficacité prouvée scientifiquement…

Des tests réalisés en laboratoire et en situation ont permis de démontrer l’efficacité de la vapeur. Les résultats observés révèlent une élimination totale des bactéries, virus, levuricide et fongiques sur les surfaces traitées.

Le traitement écoresponsable est certifié par la norme NF T72-110.

Les appareils Sanivap sont des dispositifs médicaux de la Classe IIa – Organisme notifié GMED 0459.

La gamme de produits Sanivap

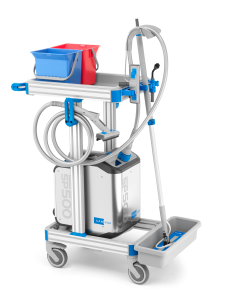

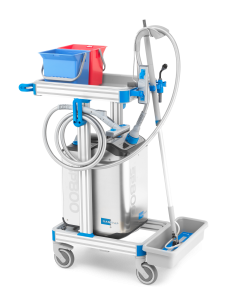

La gamme Sanivap propose des générateurs vapeur seuls ou en kits, pour une meilleure ergonomie de travail.

Le kit comprend un chariot ainsi qu’une gamme étendue d’accessoires pour un traitement complet et efficace quelque soit l’environnement à bionettoyer.

Les kits

Les accessoires

Les formations

En tant qu’organisme de formation certifié Qualiopi pour des actions de formation, Sanivap propose deux types de formation à destination :

- des collaborateurs et personnels en charge de l’hygiène et de la propreté pour l’utilisation de nos générateurs vapeur.

- des collaborateurs techniques en charge de la maintenance et réparations de nos dispositifs.

« La certification Qualiopi atteste de la qualité du processus mis en œuvre par les prestataires d’actions concourant au développement des compétences (PAC) qui souhaitent accéder à des fonds publics ou mutualisés« .

Pour toute acquisition de nos appareils, la formation à l’utilisation de nos dispositifs et aux bonnes pratiques du bionettoyage est inclue et obligatoire. Des formations complémentaires peuvent être prévues sur simple demande, un devis vous sera alors établi.

Notre formation dispense les bases théoriques de la propreté à travers les solutions pratiques et concrètes de l’utilisation de la solution complète de nettoyage et de désinfection à la vapeur sèche Sanivap.

Si vous êtes un établissement ayant acquis plus de 8 appareils ou si vous êtes distributeur de nos solutions, la formation technique est aussi obligatoire.

Découvrez le programme de notre formation bionettoyage Sanivap : ICI

L’AGEFIPH nous accompagne pour proposer nos formations à des personnes en situations de handicap. Nous nous adaptons selon vos besoins.

Pour plus de renseignements, n’hésitez pas à nous contacter.

Pour télécharger notre certification QUALIOPI : ICI

Dans cet épisode, Cécile Clavère, Responsable Bionettoyage GHT Plaine de France et Responsable service LABEL nous fait un retour d’expérience sur l’utilisation de la solution Sanivap au sein du CH de Gonesse.